Integra Resources Corp. (TSX-V: ITR) (NYSE American: ITRG)’s DeLamar drill program in southwestern Idaho continues to exceed the company’s expectations for grade and intercepts.

On Friday, the company announced the results from the DeLamar metallurgical drill program and 24 extra holes from the 11,000 meters stockpile drill program at the project. The stockpile drill program results could extend the heap leach mine life, boosting the strong economics of the DeLamar Project.

The following metallurgical drill results were seen at the DeLamar program:

- IDM-22-211: 0.41 g/t Au and 75.37 g/t Ag (1.38 g/t AuEq) over 66.90. Including 0.38 g/t Au and 1,251.00 g/t Ag (16.48 g/t AuEq) over 1.83 m

- IDM-22-214: 0.62 g/t Au and 7.85 g/t Ag (0.72 g/t AuEq) over 32.00 m

Metallurgical drilling assesses the feasibility of extracting and processing minerals determining the ore’s suitability and offering insight into its metallurgical characteristics. On the other hand, stockpile drilling involves extracting ore from a stockpile to measure its mineral quantity and quality.

The company also announced the stockpile drill program results including:

- NDM-22-037: 0.25 g/t Au and 21.38 g/t Ag (0.52 g/t AuEq) over 102.11 m

- NDM-22-040: 0.34 g/t Au and 18.19 g/t Ag (0.58 g/t AuEq) over 83.82 m

- NDM-22-050: 0.28 g/t Au and 53.26 g/t Ag (0.97 g/t AuEq) over 24.38 m

- NDM-22-136: 0.32 g/t Au and 14.28 g/t Ag (0.50 g/t AuEq) over 85.34 m

- NDM-22-147A: 0.32 g/t Au and 19.60 g/t Ag (0.57 g/t AuEq) over 42.68 m

- NDM-22-143: 0.23 g/t Au and 19.25 g/t Ag (0.48 g/t AuEq) over 67.06 m

Read more: Integra Resources finds ‘unexpected’ positive results at Idaho’s DeLamar drill program

Read more: NevGold Corp. gets exploration notice approval from Bureau of Land Management

Following the successful unveiling of the first 10 drill holes from the stockpile drill program in December 2022, the company revealed the results of the next 24 drill holes from the same program.

These drill holes further showcase the immense potential for value in the 60 million-ton stockpile of gold and silver-rich minerals left behind by former mining operators.

“Today’s drill results are well within our expected grade range of 0.3 g/t AuEq to 0.6 g/t AuEq and have the potential to provide material to further expand the heap leach mine life at DeLamar,” Integra Resources CEO George Salamis said in a statement.

“This material could enhance the strong economics of the project presented in the 2022 Pre-feasibility Study while also creating significant value from the portion of backfill material that was proposed to be handled as a pre-stripping cost in that study,” said Salamis.

The company has increased the number of drilling machines on the project to three with the aim of completing an updated estimate of the resources in the first half of 2023.

Besides the results from the drilling, the mineralization found in the metallurgical drill holes that were disclosed today highlights the high concentrations of gold and silver at DeLamar, as well as the substantial thickness of these minerals.

Salamis said the metallurgical drilling results are noteworthy because they surpass the average grade found in the current deposit, demonstrating the further potential for growth in the project.

So far, the company has tested North DeLamar backfill and Stockpiles 1 and 2. A total of 86 drill holes, amounting to 3,980 m, have been drilled as part of this program. The remaining stockpiles will be drilled in the upcoming months.

Read more: NevGold starts drilling at Nutmeg Mountain property

Read more: 2023 will be a ‘very strong’ year for gold mining: NevGold

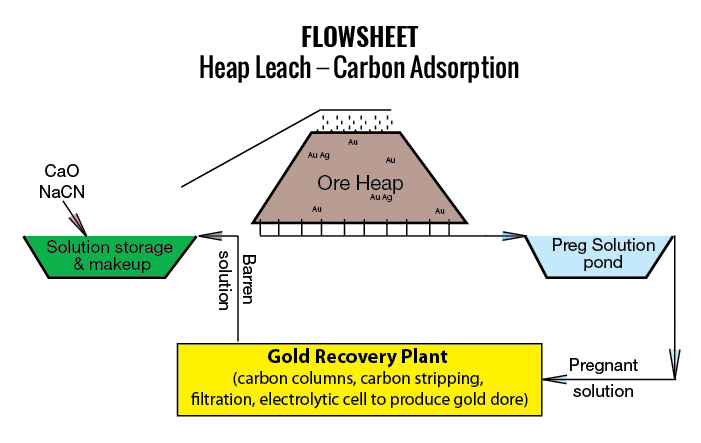

Heap leaching is a low-cost method of recovering minerals and materials from ore

The company’s stockpile drilling has mostly found oxide material with some mixed material. Hot cyanide shakes of the drilled material indicate strong heap leach recovery potential.

Heap leaching is a process used in mining to extract valuable metals and minerals from ore. The process involves stacking crushed or run-of-mine ore into a pile or “heap” on top of an impermeable liner and then leaching the minerals out of the ore with a cyanide or sulfuric acid. The solution percolates through the heap, dissolving the valuable minerals, and is then collected at the bottom of the heap for further processing.

Graph via Canadian Mining Journal.

Heap leaching is often used for low-grade ore deposits that are not economical to process using conventional techniques, such as milling and flotation. It is also used for copper and gold recovery from ore that has been previously processed by other means, such as milling.

Heap leaching is a relatively low-cost method of recovering minerals and metals from ore, as it requires fewer inputs (labour, energy, and capital equipment) compared to other methods.

However, heap leaching also has some disadvantages, including a long process time and the release of toxic chemicals into the environment if proper safeguards are not in place.