Copper miners are increasingly digging through the past to fuel the future, turning vast waste piles and unconventional technologies into new sources of supply as prices surge and shortages loom.

The push reflects a broader scramble to secure copper, a metal essential to power grids, electronics, and the data centres expected to support an AI-driven economy. In addition, benchmark London copper prices have climbed above USD$13,000 per tonne, driven by tight supply, mine disruptions, and rising demand expectations for the 2030s.

Major producers are now rethinking material once dismissed as useless. BHP Group Ltd. (NYSE: BHP), Rio Tinto Group (NYSE: RIO), Freeport-McMoRan Inc. (NYSE: FCX), and Vale S.A. (NYSE: VALE) are researching ways to extract copper from old dumps, low-grade stockpiles, and abandoned sites. Furthermore, waste rock and tailings have shifted from liabilities into potential assets.

At the massive Resolution project in Arizona, jointly developed by BHP and Rio Tinto, executives see discarded material as a long-term prize. The mine’s leadership has described copper trapped in waste mounds as the industry’s ultimate objective, because it could unlock supply without building entirely new operations. Further, miners across the sector increasingly frame waste recovery as the next major growth frontier.

The renewed interest comes as companies chase scale through consolidation. Rio Tinto and Glencore plc (LON: GLEN) recently confirmed they resumed talks on a possible merger to form the world’s largest mining group. In addition, Anglo American plc (LON: AAL) and Teck Resources Ltd. (NYSE: TECK) agreed to a USD$60 billion combination last year, reflecting pressure to secure future-facing metals.

Read more: S&P Global predicts major rise in copper demand brought on by AI

Miner is studying if copper can be recovered from waste rock

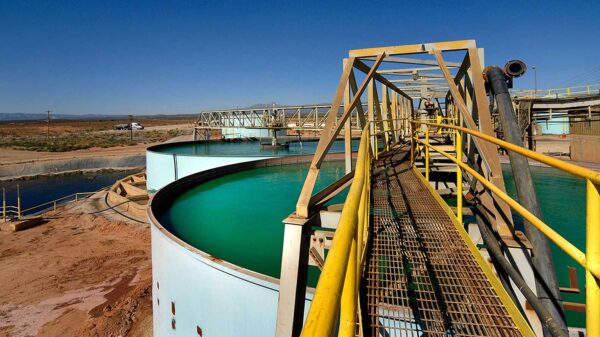

Building new mines, however, takes years and billions in capital. As a result, miners increasingly seek faster, cheaper gains from existing footprints. Freeport-McMoRan has focused heavily on advanced leaching, a process that dissolves copper from crushed rock using acidic solutions. Subsequently, the company expects new leaching methods to deliver most of its planned U.S. copper production growth by 2030.

Company executives say improved data tools now help pinpoint copper concentrations inside massive stockpiles. Consequently, applying these techniques across U.S. operations could match the output of a large new mine, without the same permitting or construction risks. Additionally, leaching economics have improved enough to justify revisiting material once considered too low-grade.

BHP is pursuing similar ideas in Arizona. The miner is studying whether copper can be economically recovered from tens of thousands of tonnes of layered waste rock left from earlier activity. Furthermore, company officials believe such sites could become meaningful supply sources as demand rises and ore grades decline elsewhere.

Rio Tinto is also experimenting beyond chemistry. In December, the company announced it produced industrial-scale copper using microorganisms for the first time. This approach relies on naturally occurring microbes that accelerate chemical reactions during leaching when added to crushed ore.

This technology sits within Rio’s Nuton venture, which has spent decades adapting bacteria to harsh mining conditions. Meanwhile, microbes are grown in bioreactors before being deployed on ore piles to improve recovery rates. Company technologists say the organisms effectively unlock copper trapped inside complex mineral structures.

Read more: Analysts forecast surge in copper consumption outside China by 2031

Critical minerals in waste could reduce reliance on imports

Interest has already emerged from outside mining. This month, Rio Tinto said Amazon.com Inc. (NASDAQ: AMZN), through Amazon Web Services, would become Nuton’s first customer, using the copper in U.S. data centres. Additionally, executives view the deal as early validation of a method they believe could reshape the industry.

U.S. policymakers have taken notice as well. The federal government has directed agencies to map domestic mine waste and streamline rules for reprocessing it. In addition, officials argue that critical minerals stored in waste could reduce reliance on imports and strengthen supply security.

As copper demand accelerates and new mines remain slow to develop, yesterday’s waste increasingly looks like tomorrow’s ore.

.