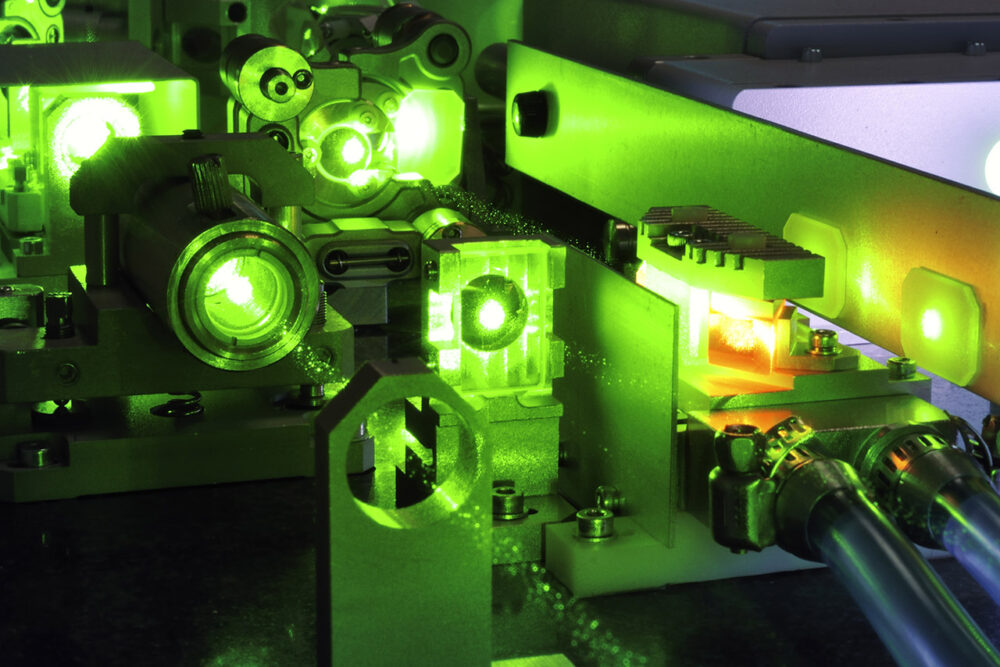

Global Laser Enrichment (GLE) is demonstrating how lasers can be used to enrich uranium in its Test Loop facility in North Carolina.

Announced on Friday, this marks a key milestone in the development of third-generation enrichment technology and signals a strategic turning point for strengthening U.S. nuclear fuel resilience.

The TRL-6 phase involves a high-fidelity operational trial under conditions that reflect scaled commercial deployment.

GLE Chief Executive Officer Stephen Long said the milestone comes after extensive system integration, engineering improvements, and repeated operational tests.

Additionally, GLE has integrated key modifications into the Test Loop to improve performance reliability. These enhancements confirm scalable enrichment efficiency and guide downstream manufacturing for Kentucky’s full-scale Paducah Laser Enrichment Facility (PLEF).

An independent engineering firm, contracted by joint venture partners Silex Systems Ltd (ASX: SLX) and Cameco Corporation (TSE: CCO) (NYSE: CCJ) will monitor and verify all test results.

Furthermore, GLE President and Chief Commercial Officer James Dobchuk emphasized the strategic importance of the position.

“Our exclusive access to the Department of Energy’s high-assay depleted uranium tails underpins a domestic, single-site supply chain solution for uranium conversion and enrichment,” said Dobchuk. “This uniquely American infrastructure, resilient to geopolitical and logistical disruptions, advances U.S. energy security and provides strategic optionality to allied nations.”

Investors have committed over USD$550 million to engineering, system design, facility development, and regulatory licensing in North Carolina and Kentucky.

The Wilmington Test Loop, with over 13,000 operational hours, remains the world’s only non governmental facility running a next generation enrichment platform.

GLE expects to produce hundreds of kilograms of enriched uranium during the TRL-6 testing phase.

Read more: Limited global uranium reserves could be gone by 2080

Read more: Molten salt reactor could be a reality in the next ten years

Laser enrichment boosts efficiency

The output and system behaviour will guide deployment strategies for the PLEF. They will also support pre licensing submissions to the Nuclear Regulatory Commission, including a formal safety case expected this summer. The SILEX laser enrichment process boosts efficiency by using highly selective laser excitation of uranium hexafluoride isotopes. This method isolates U-235 isotopes with more energy efficiency and process control than gaseous diffusion or centrifuge technologies. As reactor fuel needs diversify demand for flexible, high-assay enrichment is expected to grow.

Natural uranium contains mostly U-238 (99.3 per cent) and a small amount of U-235 (0.7 per cent). U-235 is fissile and powers nuclear reactors. Enrichment increases the U-235 concentration, typically to 5 per cent or more, to meet reactor fuel needs.

Past enrichment technologies were inefficient and costly. Furthermore, they accounted for about 30 per cent of nuclear fuel costs and 5 per cent of nuclear power generation costs. Typically, past enrichment technologies relied on energy intensive methods such as gaseous diffusion and gas centrifuge. Gaseous diffusion, used widely during the Cold War era, consumed massive amounts of electricity and required large-scale infrastructure.

Gas centrifuge technology, while more efficient than diffusion, still demanded complex mechanical systems and extended processing times. Both methods contributed significantly to nuclear fuel costs and posed challenges for scalability and proliferation control.

These older technologies now serve as benchmarks for evaluating modern systems like GLE’s SILEX platform, Furthermore, the system delivers a flexible, U.S.-based solution that enhances national security, curbs nuclear weapons proliferation, and supports clean energy.

.