Robotics company, Boston Dynamics has partnered with Google’s AI research lab to accelerate development of its next-generation humanoid robot, Atlas, with a focus on safer, more natural interaction with people.

The partnership was announced Monday during a Hyundai Motor Group press conference at CES 2026. It centers on applying advanced AI models from Google DeepMind, part of Alphabet Inc. (NASDAQ: GOOGL), to Boston Dynamics’ humanoid robotics program. Additionally, Atlas will serve as the first real-world testing platform for the collaboration.

Executives described the effort as an attempt to merge cutting-edge artificial intelligence with proven robotics hardware. The goal is to give humanoid robots stronger perception, reasoning, and social awareness around humans. Consequently, Atlas is expected to move beyond impressive athletic motion into practical, human-facing work.

“Rather than having a set of predefined, loaded tasks onto the robot, we think robots should understand the physical world the same way we do,” Parada said.

“They should be able to learn from their experience. Should be able to generalize new situations and get better over time.”

Google DeepMind plans to adapt its AI foundation models for robotics use. These systems are designed to help robots see, plan actions, use tools, and respond to people. Furthermore, the models aim to generalize across different robot bodies rather than requiring custom training for each machine.

Boston Dynamics brings commercial experience to the partnership. The company already sells the quadruped robot Spot in more than 40 countries. Meanwhile, its warehouse robot Stretch has unloaded over 20 million boxes worldwide since launching in 2023, according to Hyundai.

Read more: UBTech Robotics agrees to take 43% stake in components supplier Zhejiang Fenglong

Read more: Viral clip shows alleged spy robot at Indian-Chinese border

DeepMinds models help Atlas choose safer motions

The humanoid Atlas represents the next phase. Boston Dynamics confirmed Monday that Atlas is already in production and will be deployed to a Hyundai factory in Savannah, Georgia. Additionally, a prototype walked onstage during the press event to demonstrate its mobility and balance.

Company leaders said physical performance alone is not enough. They believe humanoid robots must communicate intent and respond predictably around workers. Consequently, natural interaction has become a central design goal rather than an optional feature.

Recent advances in AI make that shift possible, according to the partners. However, stronger cognition also raises safety concerns. Atlas combines strength, speed, and dexterity, which increases the need for reliable human awareness.

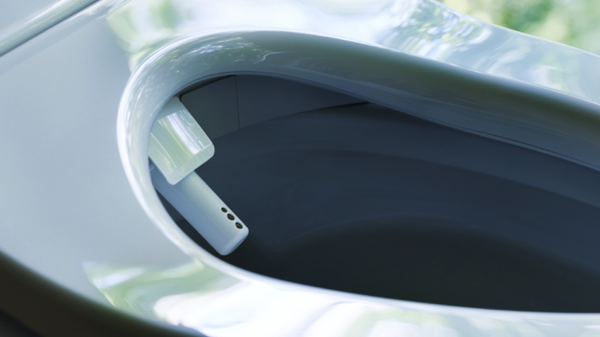

The production version of Atlas has 56 degrees of freedom using rotating joints. It also features human-scale hands with tactile sensing. Additionally, the robot can lift up to 110 pounds and repeat complex movements for long periods.

Hardware already plays a role in safety. Atlas uses 360-degree cameras to detect nearby people and obstacles. However, software determines how the robot reacts once it sees them. Consequently, DeepMind’s models may help Atlas choose safer motions and timing.

Hyundai Motor Group, led by Hyundai Motor Company (KRX: 005380), plans to introduce Atlas into factory workflows this year. Initially, the robot will support industrial tasks rather than consumer uses. Furthermore, Hyundai expects broader deployment for operations like parts sequencing by 2028.

Read more: The trajectory of artificial intelligence in 2026: A Mugglehead roundup

Read more: McDonald’s pulls Grinchy AI made Christmas ad after avalanche of complaints

Center will train robots on movements

To support that rollout, Hyundai announced a new U.S. facility called the Robot Metaplant Application Center, or RMAC. The center will train robots on movements such as lifting, turning, and navigating factory layouts. Additionally, engineers will use the site to refine robot behavior before deployment.

Training data from RMAC will feed into Hyundai’s Georgia factory systems. Meanwhile, real-world operational data will continuously update the robots through a shared software platform. Consequently, Atlas is expected to improve performance and safety over time as it learns from experience.

The partnership reflects a broader push to move humanoid robots from demos into daily industrial use. However, success depends on earning trust from human workers who will share space with them.

.