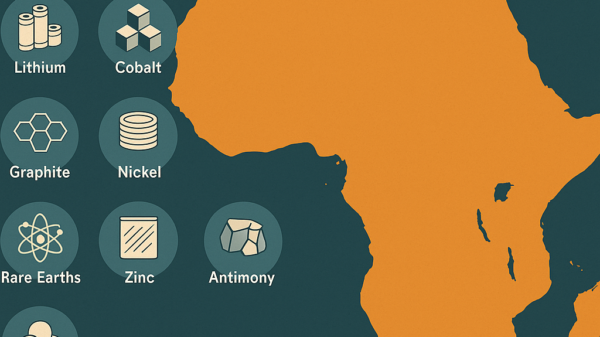

The United States Department of Energy (DOE) awarded a USD$10 million contract to the American Battery Technology Company (NASDAQ: ABAT) for its $20 million project, which involves building low-cost and low-environmental impact critical battery materials.

Announced on Thursday, American Battery Technology is leading an industry collaboration with three public universities, three national laboratories and one private corporation. Together, they have secured a competitive grant from the U.S. DOE, receiving $10 million in funding, and they’re contributing an additional $10 million in resources, making the total project investment $20 million.

The collaboration has been chosen as one of only five companies nationwide to receive funding under the Bipartisan Infrastructure Law.

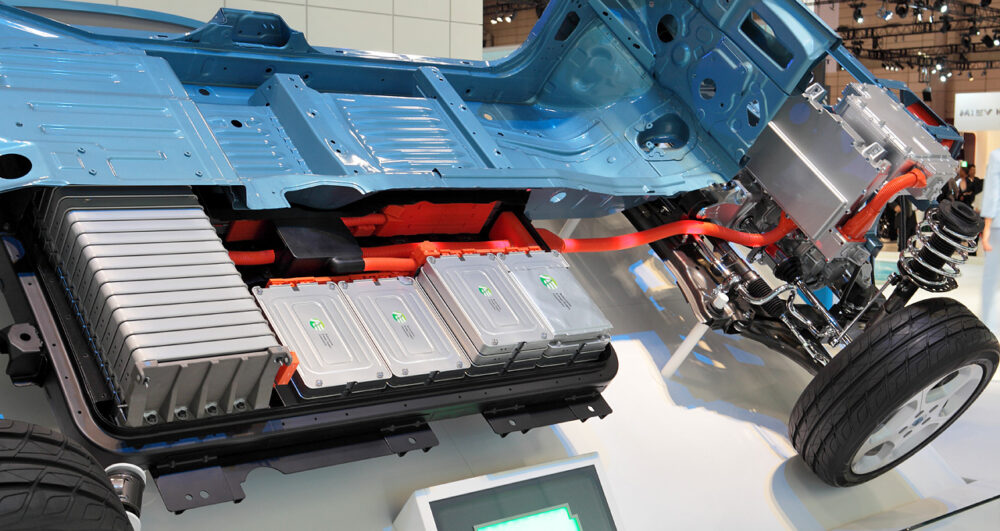

It will use this funding to develop and test three innovative technologies for recycling electric vehicle batteries. The goal is to make battery recycling more economically viable, reduce environmental impact and reintroduce more battery components into the domestic manufacturing market. The project is set to begin on October 1, 2023.

“It is an important milestone to be commissioning the initial portion of our integrated lithium-ion battery recycling facility to be able to provide domestically produced low-cost and low environmental impact battery metals to our strategic customers,” said American Battery CEO Ryan Melsert.

“However, any company that is complacent with current technologies will not be competitive in the future, which is why we are also prioritizing our pipeline of new advanced technologies that are being evolved through our research, bench development, piloting and commercialization infrastructure.”

Read more: FPX Nickel enters MOU with Japanese partners to strengthen battery metal supply chain

Read more: Lithium-ion battery market set to reach $18.8B by 2032: Allied Market Research

American Battery Technology is launching recycling operations

The company is in the process of launching the first stage of its large-scale lithium-ion battery recycling operations at its facility in the Tahoe-Reno Industrial Center. Its approach involves disassembling batteries and carefully extracting chemicals to efficiently recover materials. This method is cost-effective and eco-friendly, setting it apart from traditional recycling methods that often involve high-temperature melting or less efficient shredding systems.

Additionally, American Battery and its partners are also working on advanced separation and processing techniques at smaller scales while the lithium-ion battery recycling system is being set up and tested.

These innovations will eventually be incorporated into the large-scale system to recover more products and reduce energy, water and greenhouse gas emissions. With support from the U.S. DOE, the company and its partners are validating and improving these technologies in the lab, making test batches for partners to evaluate and then scaling up the systems for use in American Battery’s recycling operations.

American Battery Technology Company shares dipped 3.8 per cent to $8.42 on Thursday on the NASDAQ exchange.

joseph@mugglehead.com