Researchers from public research university, ETH Zurich, have found a novel way to use cheese byproducts to aid with mineral recycling.

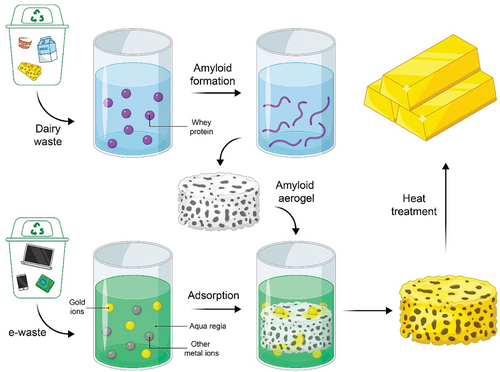

Cheese makers separate curds from whey, producing nearly nine pounds of watery by-product for every pound of cheddar. This leftover whey contains proteins that, when heated in acid, twist into ultra-thin amyloid fibrils.

Researchers in Zurich discovered they could use these fibrils to create a feather-light sponge that attracts gold more than other metals found in shredded electronics. They mixed the fibrils into a gel and dried it into an aerogel—an airy material similar to Styrofoam, but on a much smaller scale.

This aerogel contains microscopic pores that weave through it, creating vast surface area within a cube no bigger than a crumb.

When dipped into a beaker of dissolved circuit boards, the sponge quickly attracts gold ions, which stick to its proteins. In early tests, the aerogel captured more gold than the plastic resins recyclers usually use.

Even better, the process avoids toxic solvents. It relies on water, moderate heat, and protein chemistry to do the work—cutting both risk and cost.

The team ran a lab test using metal parts from twenty old computer motherboards. They dissolved the parts in acid and added a small piece of aerogel. The mix contained copper, nickel, and cobalt, but the sponge pulled gold out much more effectively.

After a short soak, the liquid cleared—showing most of the gold had left the solution. The results stood out. The sponge recovered gold that was about 90.8 per cent pure on the first try. Other materials usually need extra steps to reach that level of purity.

Read more: Calibre Mining values women’s contributions to its operations

Read more: Equinox Gold acquires Calibre Mining for $2.6B

Full process is cost effective and safe

Pulling gold ions from liquid is helpful, but turning them into solid metal matters more. The Zurich team heated the gold-filled sponge until the ions lost their charge and formed shiny flakes.

As heating continued, the flakes fused into a nugget weighing about 450 milligrams. Tests also showed it was 91 per cent gold and 9 per cent copper—matching 22-carat purity again.

The heat also burned off the protein base. Made from whey, it left no synthetic residue behind, making cleanup easy. Plastic resins don’t burn as cleanly.

The full process costs about fifty times less than the market value of the gold it recovers. Even after adding labour and overhead, recyclers could earn a solid profit. Lower costs make small, local recycling plants possible. Communities could process old electronics nearby, cut shipping emissions, and keep revenue local.

Gold gets the spotlight, but the sponge can do more. With small changes to pH or protein design, it could collect copper, cobalt, or palladium—key metals for batteries and sensors.

The team is also testing pea-protein waste from plant-based milk and collagen from fish scales. These options reduce reliance on dairy and guard against supply shortages.

The sponge could help beyond e-waste. Factories that make microchips or use gold plating also rinse out trace metals. A modular sponge could fit into these systems, saving money and cutting pollution.

The route followed to generate value via pure gold, extracted from food waste (whey). E-waste as starting source materials. Image via Advanced Materials.

Read more: NevGold pulls critical mineral antimony from Limo Butte property in Nevada

Read more: NevGold uncovers high-grade multi-metallic mineralization in Idaho

Sponge helps battery makers reclaim key metals from e-waste

E-waste is the fastest-growing waste stream on Earth. In 2024, it will reach about 63 million short tons, says the UN. Only a small portion gets recycled at certified facilities. Most old electronics end up in landfills or backyard workshops.

These sites often leak metals into the ground, polluting water with toxic chemicals. A better solution is to recover precious metals safely—before the devices reach the trash.

Furthermore, this protein-based sponge technology has many industrial uses. Electronics recyclers can recover gold, copper, cobalt, and palladium from old devices.

The sponge also helps battery and sensor makers reclaim key metals. In microchip fabrication, it captures trace metals from rinse water. Gold-plating and jewelry shops can use it to recover lost gold.

Mining companies like NevGold Corp (CVE: NAU) (OTCMKTS: NAUFF) (FRA: 5E50) or Calibre Mining Corp (TSE: CXB) (OTCMKTS: CXBMF) (FRA: WCLA) might use it to extract metals from low-grade ores. It could also be used for tailings processing, and the protein-based sponge could help recover these valuable metals in an environmentally friendly and cost-effective manner.

Furthermore, wastewater plants can remove heavy metals before discharge, cutting pollution. Small towns could also build local recycling centers, reducing transport emissions and keeping revenue nearby. This simple tool opens the door to cleaner, cheaper metal recovery.

.

NevGold Corp and Calibre Mining are sponsors of Mugglehead news coverage

.