United States Antimony Corporation (NYSE American: UAMY) said it has quietly helped bring a new commercial scale antimony processing technology to market through a hydrometallurgical facility in Bolivia.

The company said on Wednesday that this marks a significant shift in how the critical mineral can be refined outside China and Russia.

United States Antimony has funded and assisted development of the Bolivian facility since mid 2025, allowing the operation to expand roughly 15 times beyond its original planned size and output. Consequently, the plant now produces antimony flake at volumes suitable for commercial shipment to North America.

Under an exclusive agreement, US Antimony will receive all processed antimony flake from the Bolivian operation for final processing at its North American smelters. Additionally, the first shipment, totaling about 150 tonnes, is expected to arrive in February or March 2026 at the company’s recently expanded Thompson Falls smelter in Montana.

Management said the unusually high quality of the material should allow markedly higher throughputs at its upgraded smelters. Furthermore, the company expects the feedstock to meet military specifications for both antimony metal and antimony trioxide products.

Antimony is used in flame retardants, batteries, alloys, semiconductors, and military applications, yet global supply remains highly concentrated. China and Russia dominate production, while Western nations have struggled to secure reliable sources that meet defense and industrial standards. Consequently, US Antimony has positioned its processing strategy as a response to growing supply chain and national security concerns.

The Bolivian facility uses hydrometallurgical techniques rather than traditional gas fired smelting. Unlike conventional methods, hydromet processing relies on chemical leaching and electrochemical recovery.

Read more: NevGold delivers major growth at Idaho gold project

Read more: NevGold Corp. advances toward gold-antimony resource with expanded Nevada drilling

Leaching process dissolves small amounts of arsenic

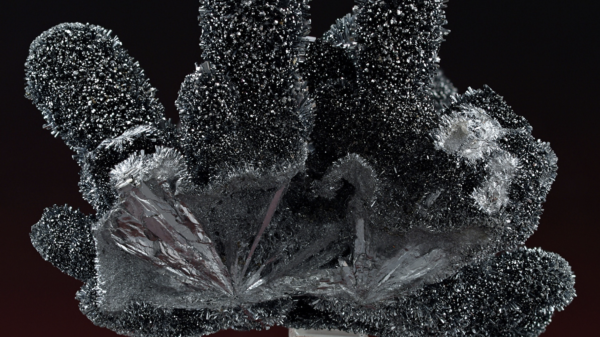

The company said the process targets concentrates such as stibnite and tetrahedrite, which both contain antimony. Additionally, the system can adapt to other metallic concentrates or high grade ores that host critical minerals.

In practice, operators batch leach antimony bearing concentrates in heated solutions inside mild steel tanks. The solution combines recycled electrolyte from later stages with additional reagents. Consequently, antimony dissolves into the liquid while most unwanted minerals remain solid.

The leaching process also dissolves small amounts of arsenic, except for arsenopyrite, which stays largely intact. Subsequently, sulfide compounds bind the dissolved antimony into stable chemical complexes suitable for electrochemical recovery.

That solution then feeds an electrowinning circuit, where electricity drives antimony metal onto cathode plates. Additionally, the antimony deposits as a brittle, non adherent layer rather than a fused coating.

Workers periodically remove the cathodes and strike them lightly with pneumatic hammers. As a result, the antimony flakes off cleanly and falls into collection bins for further handling.

Management said the system also creates valuable byproducts. For stibnite concentrates, the remaining solid residue can undergo precious metal recovery, including silver extraction. Meanwhile, tetrahedrite residues can be oxidized to extract copper, after which remaining material can yield silver and other critical elements.

US Antimony executives said the Bolivian project represents the first commercial scale hydromet antimony operation to reach market. Additionally, they emphasized that the company funded most of the facility’s development costs through a cooperative agreement with an international engineering and chemistry team.

Read more: NevGold delivers major growth at Idaho gold project

Read more: GoldMining chooses to retain its NevGold shares for next 18 months

US Antimony filed funding request with Department of Energy

The company said it expects to announce plans soon to duplicate the Bolivian plant, with added patented processes, at one or more sites in the western United States or Alaska. Furthermore, US Antimony will completely control those facilities.

Executives described the technology as especially valuable because it can upgrade low grade antimony ores. In many cases, traditional smelters cannot economically process material containing less than 10 per cent stibnite. However, the hydromet approach allows those ores to be converted into finished products meeting military standards.

The company said its existing gas fired smelters cannot complete those final refining steps on their own. Consequently, hydromet processing fills a critical gap in its production chain.

Chief executive Gary C. Evans said the company has already begun seeking government support to expand the technology domestically. On January 15, 2026, US Antimony filed a funding request with the Department of Energy tied to a proposed U.S. based hydromet facility.

The total program outlined in the request carries an estimated cost of USD$44 million. Additionally, the company is preparing a similar funding application to the Department of War for another facility near Montana.

Evans said those locations would host state of the art antimony processing plants designed to strengthen North American supply. Furthermore, he said the company continues to work regularly with multiple divisions of the U.S. government on critical materials initiatives.

US Antimony operates as a vertically integrated producer, combining mining, concentration, and processing. It describes itself as the only fully integrated antimony company outside China and Russia, a claim that has drawn increasing attention amid geopolitical tensions.

Read more: NevGold expands high grade antimony discovery at Nevada’s Limousine Butte Project

Read more: NevGold targets U.S. critical mineral supply chain with new antimony gold find

Geopolitical issues dominate the antimony market

Demand has increased as governments focus on supply chain security and defense readiness. The United States put antimony on the list of critical minerals because substitutes are limited and performance tradeoffs are severe. Furthermore, electrification, data centres, and advanced weapons systems have expanded use cases rather than reduced them.

Geopolitics dominate the antimony market. China controls the majority of global production and processing, while Russia represents another major supplier. Consequently, Western governments face concentrated supply risk tied to geopolitical rivals. Export controls, environmental crackdowns, and domestic stockpiling have already tightened availability in recent years.

Additionally, China has periodically restricted exports of antimony products, pushing prices higher and forcing buyers to seek alternatives.

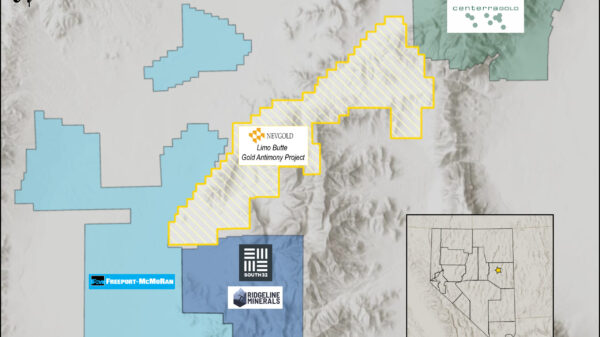

Several junior and mid-tier miners now offer exposure to that theme. NevGold Corp (CVE: NAU) (OTCMKTS: NAUFF) (FRA: 5E50) is advancing exploration projects in Nevada that include antimony alongside gold. The company has drawn attention for targeting antimony-rich systems in a U.S. jurisdiction viewed as politically secure. Additionally, its projects align with federal efforts to rebuild domestic critical-minerals supply chains.

Perpetua Resources (NASDAQ: PPTA) (TSE: PPTA) represents one of the most advanced antimony options in the United States. Its Stibnite Gold Project in Idaho hosts one of the country’s largest known antimony resources. Furthermore, the project has received strong federal backing because of its potential to supply both gold and defense-grade antimony.

.

NevGold Corp is a sponsor of Mugglehead news coverage

.