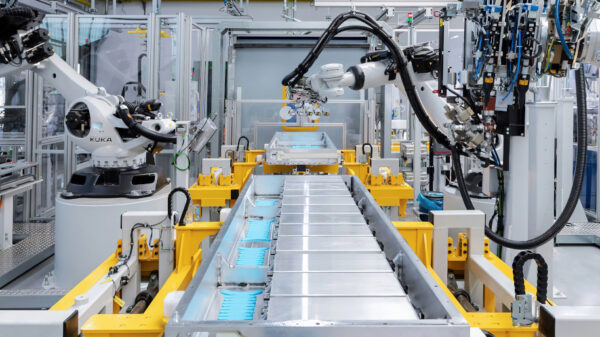

Pennsylvania State University (Penn State) and Vancouver-based lithium junior Hertz Lithium Inc. (CSE: HZ) (OTCQB: HZLIF) (FSE: QE2) have joined forces to advance a novel lithium extraction technology.

The company said on Friday that the technology lowers both the cost and energy consumption related to lithium extraction from alpha spodumene. Alpha spodumene is a common type of rock used to obtain high-quality lithium, but the current extraction process is energy-intensive.

Penn State is developing a new lithium extraction method, which Hertz Lithium will test once it’s ready for commercial use. This method involves using leaching instead of the current processes of high-temperature roasting and acidic baking.

Currently, the extraction of lithium from alpha spodumene involves subjecting the mineral to intense heat, typically around 1,100 degrees Celsius, to convert it into beta spodumene. After that, beta spodumene undergoes a sulfuric acid baking process at approximately 250 degrees Celsius to extract lithium from the water-soluble lithium sulfate.

“Both of these processes [modifying the crystals and acid baking] are very energy intensive and also require a significant amount of chemicals,” said Mohammad Rezaee, researcher and associate professor of energy and mining engineering at Penn State.

“That process generates about nine tonnes of CO2 per tonne of the produced lithium carbonate equivalent.”

The new process involves the introduction of sodium hydroxide to the spodumene concentrate, which transforms the spodumene into a soluble phase through conventional heating, although microwave roasting is also under consideration as an alternative.

Even if the new method determines that conventional roasting works better than microwaves, the new heating process will only reach temperatures of 220 degrees Celsius, significantly lower than the 1,100 degrees required for traditional roasting.

After conventional heating, alpha spodumene is converted into a soluble phase, and approximately 90 per cent of the lithium is recovered through acid leaching. Microwave sodium hydroxide roasting and water leaching also result in the recovery of more than 90 per cent of the lithium.

Rezaee explains that the process reduces greenhouse gas emissions by eliminating calcination and the use of chemicals for acid baking. In standard practice, after acid roasting a chemical treatment using base chemicals is applied to raise the pH of the acidic solution above 10. However, in this new method, because the lithium leachate solution is already basic, there is no need for an acidic solution treatment. The process also uses fewer chemicals and generates less waste.

“As the lithium mineral deposits get discovered and the demand for lithium for electric batteries continues to surge, the focus is now shifting to developing lithium extraction technologies that are more economical and environmentally friendly,” said Kal Malhi, CEO and Director of Hertz Lithium.

The technology process is still several years away from commercialization.

Read more: Lithium South Development expands production goals, updates PEA on Hombre Muerto lithium project

Lithium extraction from brine is expensive

The present methods of extracting lithium from brine are costly in both time and capital expenditure, according to Samco Technologies, a water filtration specialist that also offers consultations to the resources and mining industry.

Commercial lithium comes from underground brine deposits and mineral ore deposits. The methods for extracting and processing lithium from underground deposits vary depending on the source material and include lithium brine extraction. This extraction method involves access underground salar brine deposits via drilling.

The brine is pumped to the surface and directed to evaporation ponds. The brine remains in these ponds for months or even years, allowing most of the liquid water to evaporate naturally. Salar brines are highly concentrated and often contain not only lithium but also potassium and sodium.

The brine then stays in an evaporation pond for a period of time before being sent to a lithium recovery facility for extraction. Extraction is a process of chemical addition and subtraction, wherein contaminants are taken from the chemical solution while other solvents are added.

This is the variety of operation undertaken by both large and small lithium companies like Albemarle Corporation (NYSE: ALB) and Lithium South Development Corporation (TSXV: LIS) (OTCQB: LISMF) (Frankfurt: OGPQ)

The brine then undergoes filtration to separate the precipitated solids before being processed to produce saleable lithium.

Spending on front-end filtration can range from $750,000 to $2.5 million, depending on factors like filtration amount, flow rate and automation. The cost for a brine IX system falls within a similar range. For lower flow rates, around 50 gallons per minute (GPM), expect costs of approximately $300,000 to $400,000, while higher flow rates (500 to 1000 GPM) may require budgets of $1.5 to $3 million.

When it comes to membrane processes, they can be highly customized. A 50 GPM high-pressure membrane system for lithium concentration might cost between $200,000 and $400,000, whereas a larger 1000 GPM system could range from $2 to $4 million.

For a fully operational pilot plant at a 1/10 scale, the cost can range from $50 million to $150 million. Larger integrated facilities can be even more expensive, with costs reaching as high as $500 million to $1 billion USD.

The collaboration between Penn State and Hertz Lithium represents a move in the development of a more environmentally friendly and cost-effective lithium extraction technology.

By shifting away from energy-intensive processes like high-temperature roasting and acidic baking, the new method shows promise in reducing greenhouse gas emissions and chemical waste while cutting costs, and ultimately contributing to a more sustainable lithium production industry.

.

Lithium South Development Corporation is a sponsor of Mugglehead news coverage

.

Follow Joseph Morton on Twitter

joseph@mugglehead.com