Caterpillar Inc. (NYSE: CAT) has expanded its collaboration with NVIDIA (NASDAQ: NVDA) to bring artificial intelligence deeper into heavy equipment, job sites, factories, and supply chains.

The companies said the partnership is designed to reshape how work is done for Caterpillar customers, dealers, and employees. Additionally, the effort spans machines in the field, digital tools in cabs, and advanced manufacturing systems.

Caterpillar’s leadership said artificial intelligence is moving from back-office analytics into physical environments. Consequently, the company is focusing on real-time decision-making at job sites and production facilities.

Executives described the collaboration as a way to solve practical problems faced by construction, mining, and power customers. Furthermore, the technology is intended to improve productivity, safety, and operational confidence.

At the machine level, Caterpillar is equipping new and existing assets for AI-enabled operations. In addition, the company is adopting NVIDIA’s Jetson Thor platform to enable real-time AI inference directly on equipment.

Those systems allow machines to process large volumes of sensor data instantly. Consequently, Caterpillar expects equipment to respond faster to changing conditions in the field.

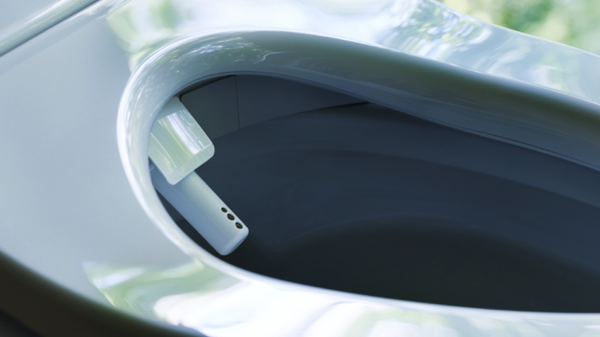

In-cab features are a central part of the strategy. Additionally, an intelligent operator assistant will provide real-time guidance, coaching, and safety alerts to equipment operators.

The assistant is designed to offer personalized insights during daily work. Furthermore, it can suggest productivity improvements based on how a machine is being used.

Caterpillar is also scaling up autonomy in construction and mining fleets. In addition, AI-driven recommendations help machines navigate complex and variable job sites.

These systems process billions of data points in milliseconds. Consequently, machines can adapt to terrain, obstacles, and changing workflows with less human intervention.

Read more: Boston Dynamics turns to AI to make humanoid robots safer around people

Read more: The trajectory of artificial intelligence in 2026: A Mugglehead roundup

System relies on Caterpillar’s Helio unified data program

Across fleets, Caterpillar is building what it describes as a digital nervous system. Additionally, AI, computer vision, and edge computing analyze sensor data in real time.

That data flows across machines and job sites. Furthermore, customers gain a clearer picture of operations without relying on manual reporting. At CES 2026, Caterpillar introduced the Cat AI Assistant as part of this push. Additionally, the company has embedded the assistant iin both digital platforms and onboard systems. The tool was built using NVIDIA’s Riva speech models. Consequently, it supports natural voice interactions with high recognition accuracy.

Operators can ask questions about equipment, parts, and maintenance. In addition, the assistant provides tailored recommendations based on context. Voice activation allows users to adjust settings or troubleshoot issues hands-free. Furthermore, the assistant connects users to Caterpillar apps and online resources.

The system relies on Caterpillar’s Helios unified data platform. Consequently, responses are based on the company’s own equipment data rather than generic sources. Beyond machines, the partnership extends into manufacturing and supply chains. Additionally, Caterpillar is using its NVIDIA AI Factory to modernize production.

The company said it is applying to forecasting, scheduling, and other planning tasks. Furthermore, it expects automation to reduce delays and inefficiencies. Meanwhile, manufacturing teams are building digital twins of factories. In addition, the company has used NVIDIA Omniverse libraries and Open USD to create the models.

The digital twins replicate physical facilities with high accuracy. Consequently, teams can test layouts and workflows before making real-world changes. This approach allows Caterpillar to identify problems early. Furthermore, it supports safer and more resilient factory operations.

Supply chain planning is another focus area. Additionally, AI tools analyze demand patterns and logistics constraints more quickly than traditional systems.

.