Battery recycling tech company Ace Green has developed an environmentally-friendly method of reusing antimony from lead-acid batteries. It converts scrap battery components into high-grade antimony alloy without the use of a smelting furnace and with zero emissions.

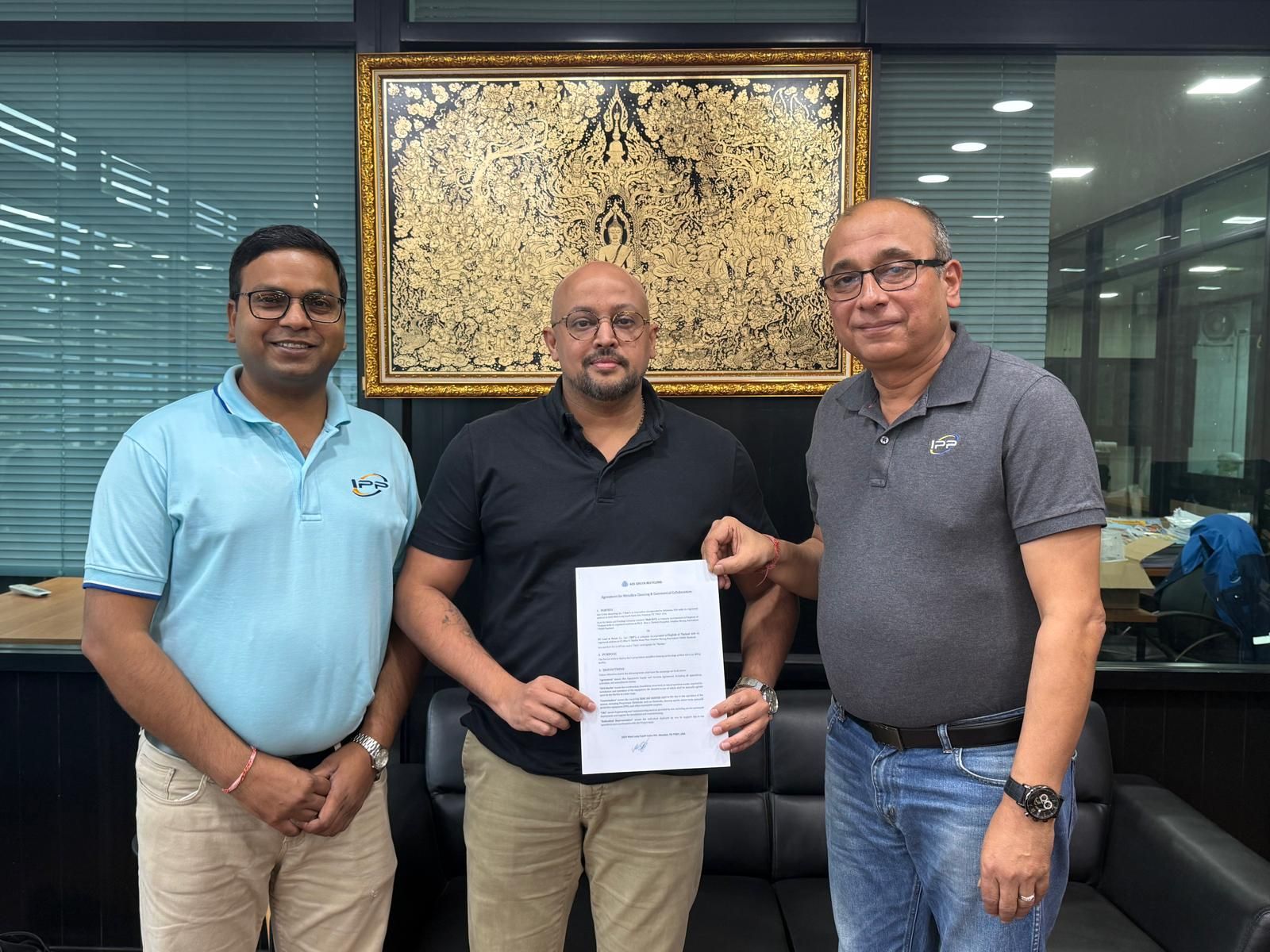

At the end of July, Ace Green deployed its Grid Metallics Processing System (GMPS) at factories in Thailand and India. The launch in these countries built on its deployment in Armenia and Taiwan. At Acme Metal Enterprises’ Taiwanese factory, the technology will be used for pulling antimony and lead out of 65 million pounds of batteries per annum.

“Our proprietary GMPS is a game-changer in the lead battery recycling industry,” Ace Green said on social media a few weeks ago, “offering a transformative solution for lead battery smelters, and creating impact, by reducing energy requirements, increasing capacity utilization of conventional furnaces and producing high value-added alloys from metallics.”

“Especially in times when prices of alloying metals like antimony are at their peak.”

The company hopes that its novel system will help alleviate upward pricing pressure for its current and future customers as the shortage resulting from China’s export controls persists.

Ace Green claims that its GMPS system will enable lead battery recyclers to boost their throughput by 25 per cent.

The reprocessing specialist’s Chief Technology Officer, Vipin Tyagi, says the method significantly cuts losses of antimony and lead that would normally be burned off during a conventional smelting process. Chemical washing involved in the extraction process is performed at room temperature. It helps eliminate toxic waste produced through other methods.

“We are seeing significant commercial interest in our GMPS from emerging markets because it provides so much value, and we look forward to bringing this innovation to more markets soon,” Tyagi said in a statement obtained by Recycling Today.

In addition to GMPS, Ace uses another patented technique called LithiumFirst to recycle commodities from lithium-ion batteries. It also produces zero emissions and no waste.

At the end of 2022, Ace signed a 15-year offtake agreement for recycled lead, lithium, cobalt and nickel with the major mining operator Glencore PLC (OTCMKTS: GLCNF) (LON: GLEN) (FRA: 8GC).

The company’s flagship facility is situated in Texas, USA. Additionally, the metals reprocessing operator has offices in Singapore and India.

The lead-acid battery market is currently valued at approximately US$13 billion while the lead recycling sector is projected to reach a valuation of US$22.3 billion by the end of the decade.

Read more: Antimony recovery results from NevGold’s Limo Butte project exceed expectations

Read more: NevGold’s latest Nevada drill results show exceptional gold mineralization

Follow Rowan Dunne on LinkedIn

rowan@mugglehead.com