Plug Power Inc. (NASDAQ: PLUG) has completed the installation of 100 megawatts of proton exchange membrane electrolyzers at Galp Energia’s (ELI: GALP) Sines Refinery in Portugal, advancing one of Europe’s largest renewable hydrogen projects.

The Monday milestone follows an initial project announcement in October 2025, when the first 10-megawatt GenEco electrolyzer module reached the site. Since then, Plug delivered and installed all ten electrolyzer arrays at the coastal refinery complex. Consequently, the project has moved from staged delivery into final system integration.

Commissioning of the electrolyzer systems is expected to begin in the coming months. Once operational, the facility should produce up to 15,000 tonnes of renewable hydrogen annually. Additionally, the output is designed to replace roughly 20 per cent of the refinery’s existing grey hydrogen consumption.

The switch to renewable hydrogen is expected to cut about 110,000 tonnes of greenhouse gas emissions each year. Those reductions cover Scope 1 and Scope 2 emissions measured in carbon dioxide equivalent. As a result, the project targets industrial decarbonization without requiring a full refinery redesign.

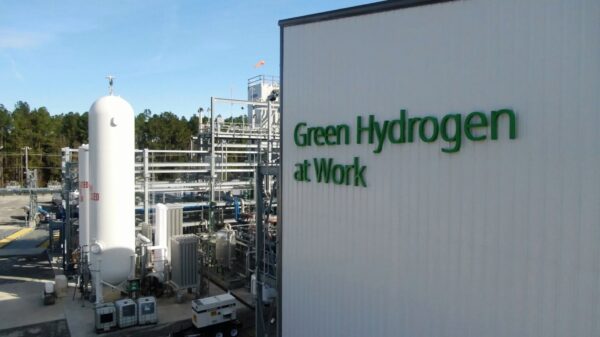

Plug executives described the installation as proof that large-scale green hydrogen infrastructure now operates beyond pilot scale. Furthermore, company leaders framed the Sines project as a working example for energy-intensive industries that cannot easily electrify operations.

Galp executives characterized the project as a turning point for European refining. In addition, the company linked renewable hydrogen production to future low-carbon fuels used in shipping, aviation, and heavy industry. Those sectors face limited alternatives to molecular fuels.

Read more: Plug Power brings green hydrogen production to Namibia

Read more: Duke Energy Florida uses solar-made hydrogen to reinvent gas power

Plus has pursued multi-gigawatt projects in multiple countries

Plug supplied its GenEco electrolyzers through a transatlantic manufacturing and logistics network. Components came from facilities in both the United States and Europe. Meanwhile, the modular design allowed installers to scale capacity in defined blocks rather than a single build.

The company has positioned Europe as a central growth market for electrolyzer deployment. Subsequently, Plug has pursued multi-gigawatt projects across Spain, the United Kingdom, and other regions. Those initiatives target refineries, fertilizer producers, and energy hubs.

Plug said its European pipeline forms part of a broader global opportunity funnel estimated at about USD$2 billion. However, the company emphasized delivery execution rather than financial projections. The Sines installation represents one of its largest completed electrolyzer deployments to date.

The refinery site at Sines already serves as a strategic energy hub for southern Europe. Consequently, the hydrogen project integrates directly into existing fuel processing infrastructure. The system is designed to supply hydrogen on-site rather than rely on transport or storage networks.

Plug continues to market its electrolyzers as industrial-scale equipment rather than experimental technology. Additionally, the company has promoted modularity as a way to shorten project timelines. The Sines project demonstrates that approach under real operating conditions.

.